Nut protein such as almond, flours like insect flour, and vegetable oils such as sunflower, are some examples of alternative protein sources that the market is betting on to meet the unstoppable growth in demand for sustainable proteins. The technological challenge lies in obtaining these protein ingredients in an economically viable, technically feasible, and sustainable way. And, this is where supercritical CO2 technology plays a crucial role. We’ll explain.

Consumers are increasingly sensitive to environmental protection and the sustainability of the products they buy, which is driving rapid growth in the international demand for alternative proteins. These opportunities can be divided into two broad categories: a growing sector offering alternatives to meat based on plant-based proteins, and, in the longer term, lab-grown meat.

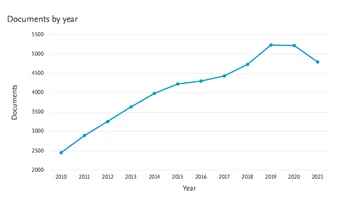

Focusing on “plant-based protein”, indeed, this opportunity, not only for the food sector since we must not forget the sector of biobased and biodegradable materials, has resulted in the publication of a large number of technical articles in specialised journals over recent years (Figure 1).

Figure 1. Number of publications with the descriptor “Plant protein” (Source: Scopus)

Supercritical CO2 Extraction Technology: An Opportunity for the Development of Plant-Based Protein Ingredients

Thus, biorefinery strategies for the comprehensive use of plant matrices as alternative nutrient sources pose technological challenges, especially in the stages of protein extraction and isolation. In this field, supercritical CO2 extraction technology is an opportunity to be valued in numerous matrices, which at AINIA we have been intensively developing for several years.

Focusing, for example, on oilseeds, their extensive cultivation has responded for decades to the great economic driver that is the demand for vegetable oils. In this way, this large market has facilitated the optimization of defatting systems to maximize yields, minimize costs, and improve the final quality of the oils.

Supercritical CO2: A Sustainable Technology for Extracting Oils, Fats, Cereals, Nuts, and Insect Flours

However, the quality of proteins can be negatively affected by these more widespread conventional systems. In this context, the use of supercritical CO2 as a solvent for extracting oils, fats, and other metabolites from these matrices is an economically viable and technically feasible alternative technology, which is also transferable to other matrices such as cereals, nuts, or insect flours. Additionally, supercritical CO2 is clean, sustainable, suitable for all markets, and applicable for products with an organic certification.

Thus, if we shift the focus from oil to the defatted matrix, supercritical technology can yield higher-quality products sometimes due to a greater presence of metabolites with antioxidant capacity, sometimes by reducing fat content (low-calorie products used as supplements or ingredients in sports-based foods), and sometimes by increasing protein content as a result of the defatting process. Products obtained in this way also improve their microbiological stability and sometimes reduce the intensity of certain unwanted flavours.

From By-products to New Ingredients with High Protein Value: The Power of Supercritical CO2

Alongside the original raw materials, numerous sources considered as low-commercial-interest co-products, such as press cakes and milling rejects from cereal processing or nut dehulling, can be viewed under this lens as materials rich in actives that can be concentrated to create new ingredients highly sought after for their high protein content for the development of new products.

At AINIA, we have experience with some of these matrices such as rice germ and bran, oilseeds like rapeseed, nut flours, press cakes from various seeds used in oil production,… Our research on process conditions enables us to:

- Promote changes or structural alterations that positively impact the technological and functional properties of proteins.

- Achieve products with final fat values below 2-3%, tailored to each intended use and market specification.

Our experience in the industrial plant enables us to achieve results that are suitable for efficient industrialization costs, allowing us to affirm that production on a contract basis is possible to meet the growing market demand.

If your company is seeking processes to obtain new natural and sustainable ingredients, AINIA can assist you. We offer solutions that are more sustainable than conventional ones, utilizing clean technologies that produce no waste.