The Good Manufacturing Practices (GMP) standards are the international designation for Correct Manufacturing Practices. Nowadays, they are applied to numerous productive sectors such as food, pharmacy, cosmetics, or health, through a series of standards and guidelines that manufacturers must follow. At AINIA, we are implementing product certification according to the Good Manufacturing Practices (GMP) ISO 22716:2007. We’ll explain how.

Originally, they were applied to the manufacturing of food, pharmaceuticals, cosmetics, and medical products. However, today, their application extends to other productive sectors. This is done through a series of standards and guidelines that manufacturers must follow.

Compliance with GMP is essential for obtaining a product that is safe for the health of the consumer and the company’s own staff.

GMP Certificates for the food sector: ISO 22000, SQF Code, ISO 9001, and HACCP

The most important GMP certificates for the food sector are:

- ISO 22000 certification, for food safety.

- SQF Code: Food Safety Management System.

- ISO 9001, for quality management systems.

- Hazard Analysis and Critical Control Points (HACCP).

Good Manufacturing Practices (GMP or similar depending on the final product) are essential in the research, development, and production of pharmaceuticals. From the manufacturer to the hospital, regardless of the size of the company, all must comply with GMP regulations.

Good Manufacturing Practices provide guidelines and guidance in areas such as:

- Quality management,

- Training and qualification of staff

- Production and testing methods,

- Qualifications of rooms, equipment, and facilities.

- Process validation (aseptic process validation)

- Validation of testing/sampling methods (environmental control)

- Validation of cleaning methods

- Validation of computerized systems.

- Appropriate packaging (labels, containers, and materials).

- Suitable and appropriate production, distribution, and storage.

Figure 2. Schematic representation of the main pillars of GMP.

Why are Good Manufacturing Practices necessary?

To maintain documentation, cleanliness, and consistency in the execution of the process for obtaining a product that is not altered between productions, certified for quality, and free from substances toxic to humans.

According to the WHO, the majority of diseases (poisonings and even deaths) transmitted by food are caused by bacteria, viruses, parasites, or chemical contaminants. Therefore, food safety is a global concern.

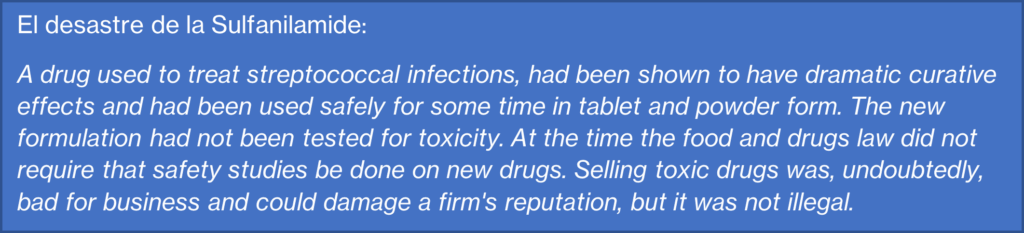

When GMP, GMP, or similar current regulations for the laboratory or facilities are not followed, headlines such as the following may occur:

Example of babies born without arms when mothers took thalidomide during pregnancy as medication for nausea.

The main causes were not following GMP regulations regarding the following points:

- Failures to follow internal procedures to prepare the necessary documentation (master production).

- Non-compliance or failure to carry out procedures applied to the control of the prevention of biological contamination.

- Errors in observing/monitoring workers entering aseptic facilities (filling areas).

How can I adapt my laboratory or workspace to comply with GMP regulations?

At AINIA, we are committed to our clients and the current quality systems. That’s why, in the biotechnology pilot plant, we are implementing product certification according to Good Manufacturing Practices (GMP) ISO 22716:2007.

- Read the GMP guide: As an initial step, one should read the guide to Good Manufacturing Practices (GMP).

- Conduct a self-inspection: The next step is to perform a self-inspection in which critical thinking and the boldness of an inspector visiting the facilities for the first time must be applied.

- Identify improvement points and draft a work plan: At AINIA, improvement points have been identified in managing the laboratory, and a work plan corresponding to the basic needs of the facilities has been drafted. These would be:

- Documentation to be updated

- Necessary equipment and its correct labeling

- Training curricula and qualifications for specific tasks

- Internal and external audits

- Raw materials and products

- Control and monitoring of the facilities

- Waste management

- Deviations and non-conformities.

As can be seen, there is one element that is always recurring:

If it’s not documented, it didn’t happen.

This golden rule leads us to one of the most important pillars of quality in laboratories and facilities: data integrity.

- Check data integrity: To determine if our current system meets data integrity requirements, we need to ask if it complies with the following definition:

- Attributable: The author is unequivocally identified. Who and when.

- Legible: Anyone can read the content.

- Contemporaneous: The information is recorded at the time it occurs.

- Original: The information is recorded in an official document or in exact and certified copies of an original document.

- Accurate: Correct data, independently reviewed revisions.

- Implement the changes and start working: The final step would be to implement the changes in the laboratory and begin working according to the guidelines mentioned in the Good Manufacturing Practices (GMP) ISO 22716:2007.

GMPs for the industrial production of active ingredients for food and pharmacy

At Altex (high-tech extractive industrial plant of AINIA), we have implemented a production system based on Good Manufacturing Practices (GMP). These standards, in place since 2013, have enabled us to enhance our presence in the market for manufacturers of active pharmaceutical ingredients (commonly known as APIs), including those intended for incorporation into medicines, as well as cosmetics or foods.

If you are interested in learning more about the process, do not hesitate to contact us, because quality involves everyone and is part of our products and customers.