Subscribe to our newsletter

- R&D&I Programmes

- Technological Services

- Consultancy Services

- Laboratory Services

- Training and Events

- Sectors

One of these prototypes detects the presence of bitartrates in real time, as well as any foreign body that may contain the inside of the bottle. In this way, the highest quality wines of the cellar are free from solidified residues and any fragment of glass or plastic. The other prototype is a pioneer in the automatic detection of oxidation defects of bottled wine. Among others, the result of potential microfiltrations of the bottle cork. These prototypes are the result of a collaborative R & D project, developed over three years by MECAL (Mecanizaciones Alavesas, S.A.) and AINIA Centro Tecnológico, with the collaboration of La Rioja Alta, S.A. This project has been financed by the Ministry of Economy and Competitiveness.

La Rioja, (Spain), November 24, 2016.- Mecanizaciones Alavesas, SA, a company specialized in the industrial machinery manufacture and equipment and AINIA Centro Tecnológico, specialist in advanced vision technologies and R & D development in food and beverages sectors, decided three years ago to join in a collaborative R & D project, financed by the RETOS program of the Ministry of Economy and Competitiveness, with the ultimate goal of developing advanced inspection prototypes capable of providing new solutions to monitor the wines quality and food safety. La Rioja Alta, SA, a leading wine cellar in the wine sector, has joined the project collaborating from the beginning, both supplying samples and lending itself to evaluate the developed prototypes in its facilities.

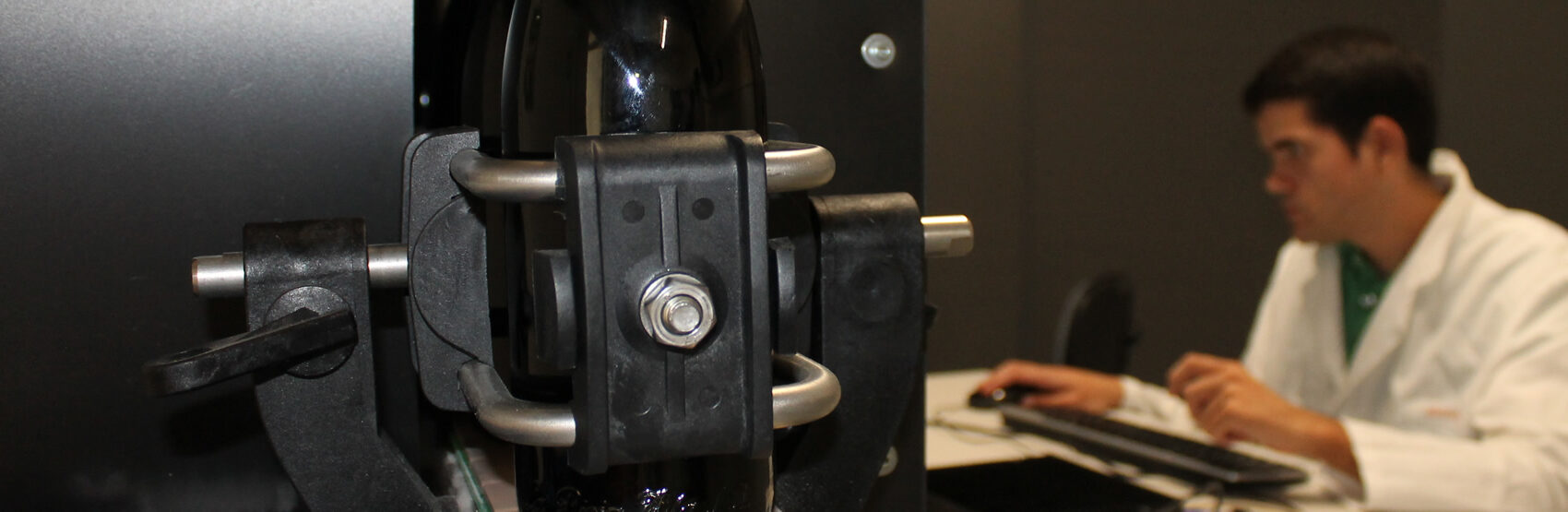

After three years of work, BOTTLESCAN project has achieved some pioneering results of great value: The development of two prototypes of advanced vision and spectroscopy for wine cellars, both installed experimentally in the bottling line of La Rioja Alta, S.A.

The bitartrates are the small sediments or crystals that sometimes we find in the wine bottles bottom of guard. They appear due to the “tartaric acid” of the grape and although they are evidence of a good wine, the consumer does not always accept it, which is why the tendency of high-level wineries is to eliminate it, trying to get a wine as clean as possible.

The prototype developed in the framework of the BOTTLESCAN project is able to detect in real time and without loss in production, the precipitated bitartrate in the bottles inspected.

This experimental prototype, based on penetrating NIR vision, is able to detect bitartrates and any other contaminants of small size (up to several millimeters) as some fragment of glass or plastic, located inside the bottle of wine while the bottles pass through the production line.

The penetrating NIR vision uses cameras with sensors especially sensitive to the near infrared spectral range, reason why they are able to detect characteristics invisible for the human eye. This application works in real time through parallel computing, processing each frame captured by the camera.

Once the prototype identifies clean bottles of bitartrates and foreign bodies, emits signals to the rest of the system that produce their classification automatically. In this way, it ensures the maximum quality of the wine that sells the winery.

Oxidation is one of the main defects in high quality wines and a constant struggle in the cellars. Excess oxidation may occur during winemaking but also after bottling, which is more difficult to detect in these cases.

An application example of the prototype is when this oxidation is produced by microfiltrations in the cork that allow oxygen to enter the bottle. These microfiltrations cause the progressive oxidation of the bottled wine, an effect that until now could not be detected until the bottle is uncorked. The developed equipment detects this type of defect, enabling a rejection of the oxidated bottle in the same production line that it has been detected.

The system also detects other characteristics of oxidized bottled wines, generating an alert in the production line that allows the exclusive selection for the commercialization of highest quality wines.

The experimental prototypes developed have been possible thanks to the collaboration between AINIA, a partner in innovation that has contributed its experience and inspection technology adapted to solutions for agro-food processes; MECAL (Mecanizaciones Alavesas, S.A.), manufacturer of equipment and industrial machinery, which has developed the prototype finalists; And La Rioja Alta, S.A, a winery that uses R & D developed, who has participated defining the characteristics of greater interest by contributing their knowledge and experience in the field of wine. The results obtained from the Bottlescan project represent a differential advantage for this winery.

The project “Inspection of integrity and safety in glass bottling lines, BOTTLESCAN” has been financed by the Ministry of Economy and Competitiveness, within the State Plan for Scientific and Technical Research and Innovation 2013-2016 and by the State R&D Program,2014 oriented to societal challenges, and co-financed with Structural Funds of the European Union.

Although the developed prototypes have the main objective of improving the bottled wines quality, they may be applicable to other sectors such as oils, soft drinks, beer and spirits drinks.

| Responsible | AINIA |

| Address | Calle Benjamín Franklin, 5 a 11, CP 46980 Paterna (Valencia) |

| Purpose | To attend to, register and contact you to resolve the request you make to us through this contact form |

| Legitimation | Your data will be processed only with your consent, by checking the box shown on this form |

| Recipients | Your data will not be transferred to third parties. |

| Rights | You have the right to request access to, correct or delete your data. You can also request that we limit its processing, oppose it and request the portability of your data by contacting our postal address or [email protected] |

| More info | You can find more information in our Privacy Policy |

| DPO | If you have any questions about how we will treat your data or would like to make any suggestions or complaints, please contact the Data Protection Officer at [email protected] or at the Data subject support form |

I consent to the use of my personal data to process my request, as set forth in your Privacy Policy

I consent to the use of my data to receive information and commercial communications from your entity.