During the 8th international scientific conference on cultured meat which took place in Maastricht from the 9th to the 11th of October (The Netherlands), international scientific speakers shared their last developments in the field. Many companies which strive for design, optimization, and support (either with materials, technology or as sponsors/investors) specialized in cultured meat, fish or even insects.

Figure 1. 8th international scientific conference on culture meat logo.

With the aim of meeting and getting familiar with new cultured meat technologies, future trends, challenges, common mistakes and innovation, the state-of-art companies and research centers, AINIA attended the 8th international scientific conference on cultured meat. Keep reading to see what the latest trends are, the latest news and companies we connected with.

During the 9, 10 and 11th of October, representative members and key speakers from leading companies such as Mosa Meat, Technion, Bluu sea food, Merck, Alep Farms, Biftek, Wildtype, Biotechne, Nutreco, ORF Genetics, PAN Biotech, Fold Changes, 3D Bio-tissues, Sartorius, Profuse Technology, Cellularevolution, BioBetter, Invest in Holland, Eppendorf, Getinge Applikon, The Kitchen Hub and Naturbeads Ltd, among other companies, shared their lasted research results and innovative ideas and updates regarding in vitro meat production and maintenance.

During this event, universities also had the opportunity to share their progress as well as suppliers and sponsors proposing their new animal free materials and alternatives to commonly used ones, with the final goal of carrying on cell culture (from animals, fish or insect) using vegetable scaffolds and animal free products.

The following universities attended and presented during the conference (among others): University of Vechta, University of Osnabrück, University of Birmingham, University of Colorado Boulder, University of Helsinki, University of Bath, Tufts University, Maastricht University, Tokyo’s Women Medical University, Waseda University, Michiya Matsusaki y Reutlingen University

What innovative ideas were presented during the conference?

Among the great diversity of keynote speakers, company pitches and informal debates, the following new trends or ideas are highlighted as innovative. AINIA is already working on some of them and learning how to implement and use the knowledge from the session for future projects.

- 3D-bioprinting Fabrication of Lab-Grown Structured Wagyu Meat

- Decellularized plant scaffolds for adipose tissue engineering

- Understanding the signals regulating muscle cell fusion

- Suitable Hydrogel-based Biomaterials Enriched with Plant Proteins for 3D

- Printing of Cultured Meat

- Production of food-grade microcarriers based on by-products from the food industry to facilitate the expansion of bovine skeletal muscle satellite cells for cultured meat production

- Cooking up edible membranes for vascularized cultivated meat bioreactors

- Bovine embryonic stem cells (bESC) as a source for industrial cultured meat production

- Microbiota-Derived Postbiotics: Alternative to Fetal bovine serum for Cultured Meat

- Reducing the Environmental Impact of Culture Media in a Cultured Meat Bioreactor: A Study of Metabolite Uptake to Inform Serum-Free Media Design

- Extracts obtained from Chlorella vulgaris induce proliferation of C2C12 myoblast cells in serum-free condition.

- Cellulose beads as microcarriers for cultured meat production

- MAPK/ERK pathway and NOTCH signaling inhibition promotes myogenic differentiation in animal free culture conditions for cultured meat production

- In vitro insect fat cultivation for cellular agriculture applications

In previous AINIA articles the basic concept of understanding the structure of the muscle cells was mentioned, as well as the work packages in which the project Smartmeat is based. This project is successfully ongoing.

During the conference, the companies and universities dedicated to the culture of in-vitro fish cells also shared their latest developments and milestones, such as:

- Structural similarity of fish fillet achieved using edible plant-based scaffolds

- Development of a Continuous Fish Muscle Cell Line for Cellular Aquaculture

- Leveraging RNA sequencing to identify factors for enhanced growth of a salmon cell line under reduced serum conditions.

- Challenges and opportunities in process development for fish cell suspension cultivation.

As per the conference’s program, every day there were companies and institutions pitches and open debates related to consumer acceptance, Academia-Company interaction and Training and Education.

The conference finished with keynote speakers and debates related to the perception of the cultured meat, fish or insects, the analysis of the future of food and the potential transition pathways of cultured meat in specific countries.

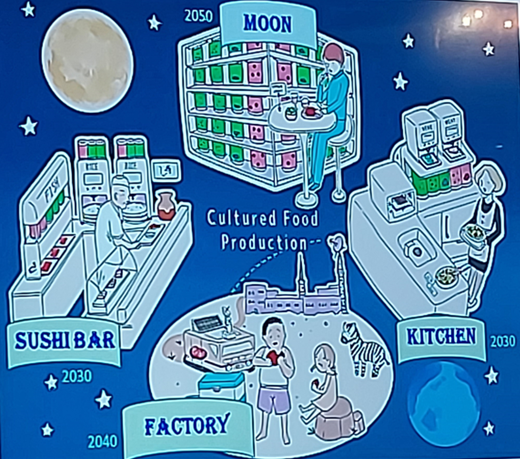

Figure 2. Future perspectives of cultured meat

Special mention is reserved for figure 2, in which it is explained that by the year 2030 everyone should be able to get cultured meat either in restaurants or bars. By the year 2040, we should be able to have it produced in a “do it yourself style” at home and the next step would be on other planets. As Tatsuya Shimizu from Tokyo’s Women Medical University, shared during his talk about Circular Cell Culture Using Algae and Animal Cells for Sustainable Food Production.

How did AINIA take part?

As part of the conference program, there was time for posters sessions and networking. During these breaks, all the attendees were able to connect and share ideas.

AINIA presented a poster which explained the foundation of the Smartmeat project and working packages execution. Either for cell culture, 3D printing, bioreactor selection and settings and growth factor production.

Figure 3. Smartmeat poster presentation.

AINIA strived for, and motivated the study, application and technology and innovation transfer during this congress.

After the International conference on cultured meat, we can highlight the importance of continued research, sharing and challenging the cultured meat development by using different platforms and transferring the acquired knowledge to our day-to-day business as well as to companies in Valencia in order to provide them with the latest technology, knowledge, materials and processes.

The strategy always aligns with the European sustainable development objectives (ODS) number 2, zero hunger, number 9, industry, innovation, and infrastructure and 12, responsible production and consumption.

Figure 4. European development objectives aligned with the Smartmeat project.